Why Material and Strength Matter When Selecting Stainless Steel Tie Wraps

Introduction

Selecting the right stainless steel cable ties directly impacts installation safety, long-term durability, and overall project reliability. Material grade, tensile strength, tie length, and environmental resistance all determine whether your system performs flawlessly—or fails early. This guide helps procurement teams make confident, cost-effective decisions backed by real data and industry-proven practices, with insights supported by XIXI’s extensive field experience.

1. Stainless Steel Grades Explained: 304 vs 316

The Backbone of Durability

The grade of stainless steel is the most important factor determining corrosion resistance, lifespan, and long-term stability. For stainless steel cable ties, the two most widely used grades are 304 and 316, each optimized for different environments.

304 Stainless Steel — The General-Purpose Standard

-

Reliable rust resistance for indoor and mild outdoor environments

-

Suitable for electrical rooms, commercial buildings, factory interiors

-

Cost-effective choice for large-volume usage

316 Stainless Steel — Marine & Chemical Grade

-

Contains molybdenum, significantly enhancing corrosion resistance

-

Performs exceptionally well in saltwater, high humidity, acids, and solvents

-

Required for coastal sites, chemical plants, food processing, maritime projects

304 vs 316 Stainless Steel: Key Performance Comparison

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good | Excellent (marine/chemical) |

| Cost | More budget-friendly | Higher investment |

| Ideal Use Cases | Indoor & mild outdoor | Marine, chemical, heavy humidity |

| Service Life | 2–5 years outdoors | 5–10 years in harsh conditions |

Real-World Case Study

A Gulf Coast manufacturing plant installed 304 stainless steel ties for outdoor cable bundles. Within 18 months, salt spray caused severe corrosion, resulting in tie failures and two shutdowns—total losses exceeded $50,000.

Switching to 316 stainless steel ties increased service life to 7+ years and reduced maintenance costs by 40%.

2. Tensile Strength & Load Capacity: Why It Matters

What Tensile Strength Really Means

Tensile strength determines how much load a tie can withstand before breaking. For industrial applications, selecting the right strength prevents failures in:

-

Cable bundles

-

Pipelines

-

Conduit lines

-

Machinery components

-

High-vibration environments

Standard Tensile Strength Ratings

| Tie Width (in) | Tie Length (in) | Tensile Strength (lbs) | Typical Applications | Flexibility |

|---|---|---|---|---|

| 0.10–0.14 | 4–8 | 50–120 | Electronics, small bundles | High |

| 0.14–0.18 | 8–14 | 120–175 | General industrial use | Medium |

| 0.18–0.25 | 14–24 | 175–250 | Heavy-duty & outdoor | Low |

How to Select the Right Strength

-

Choose a tensile strength 20–30% above your actual load

-

Avoid over-specifying to reduce unnecessary costs

-

Never use light-duty ties for heavy industrial applications

Optimization Example

A data center replaced uniform 120-lb ties with targeted options (50-lb + 175-lb), lowering material costs by 18% and improving maintenance efficiency.

3. Choosing the Right Length: Fit, Efficiency & Cost

Tie length directly impacts installation quality and material waste.

Length Guidelines

-

4–8 inches: electronics, control panels

-

8–14 inches: general cable management

-

14–24 inches: large outdoor bundles, pipelines

Procurement Tip

Measure bundle circumference → add 1–2 inches for the locking head.

Stocking 2–3 lengths typically yields the best cost-to-efficiency ratio.

Case Example

Using only 24-inch ties caused a construction team to trim excessive material—resulting in 75% waste. Switching to a size mix reduced procurement costs by 12%.

4. Environmental Resistance: Can Your Ties Withstand Harsh Conditions?

Environmental factors such as humidity, chemicals, UV exposure, and extreme temperatures heavily influence tie performance.

Recommended Material Choices

-

Marine/coastal: 316 stainless steel only

-

Chemical plants: 316 + corrosion certification

-

High UV exposure: UV-stabilized coatings

-

Extreme temperatures: Confirm -40°F to 500°F rating

Procurement Must-Do

Request:

-

Grade verification

-

Tensile strength test data

-

Corrosion performance reports

This prevents failures caused by substandard or incorrectly specified materials.

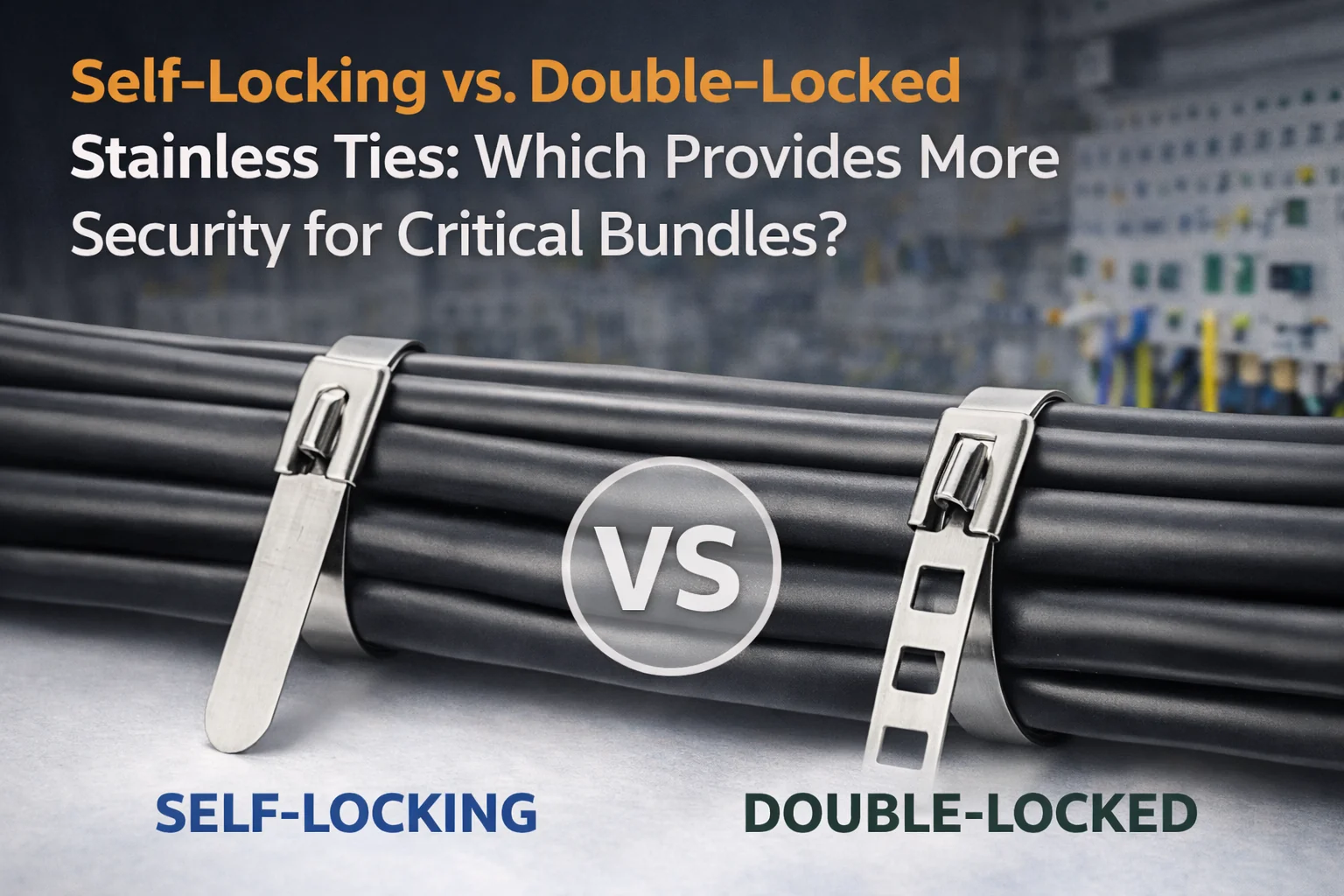

5. Locking Mechanisms: Strength, Security & Efficiency

Locking design determines strength, reliability, and installation speed.

Common Lock Types

Self-Locking

-

One-way mechanism

-

Permanent and secure

-

Ideal for large-volume installations

Releasable/Reusable

-

Adjustable and reusable

-

Lower tensile strength

-

Suitable for server rooms or maintenance-intensive setups

Heavy-Duty Locking Head

-

Reinforced structure

-

Required for loads over 175 lbs

-

Used in grids, pipelines, outdoor electrical systems

Use Case Result

After switching to heavy-duty locking heads, a utility company saw a 90% reduction in tie failures on overhead power lines.

6. Frequently Asked Questions (FAQs)

Q: What’s the difference between 304 and 316 stainless steel ties?

316 includes molybdenum for superior corrosion resistance.

Q: How much weight can stainless steel cable ties hold?

Typically 50–250 lbs depending on width and design.

Q: Are stainless steel ties UV resistant?

Yes, but UV-stabilized coatings improve longevity.

Q: Can they be reused?

Standard ties are not reusable; releasable options are available.

Q: What length should I choose?

Bundle circumference + 1–2 inches is the best rule.

Q: Are they suitable for food processing?

Yes—316 stainless steel meets food industry standards.

Conclusion

Stainless steel cable ties are essential components that influence system safety, longevity, and maintenance cost. By choosing the correct grade (304 vs 316), tensile strength, length, and locking mechanism, you can significantly improve performance and reduce risk.

Whether you’re managing marine installations, chemical facilities, commercial wiring, or heavy industrial projects, selecting the right tie wrap ensures long-term reliability.

Explore XIXI’s full range of 304 and 316 stainless steel cable ties—including self-locking, heavy-duty, and marine-grade options—and secure your projects with confidence.