Stainless Cable Ties,Stainless Steel Zip Ties BLOG

Admin

High-Temperature Stainless Steel Zip Ties: Materials and Ratings Explained.

In demanding industrial environments, ordinary fastening solutions can fail catastrophically when temperatures rise. For securing cables, hoses, and components in furnaces, engine bays, exhaust systems, or industrial ovens, you need a solution engineered to withstand the heat. High-temperature stainless steel

Read More →Admin

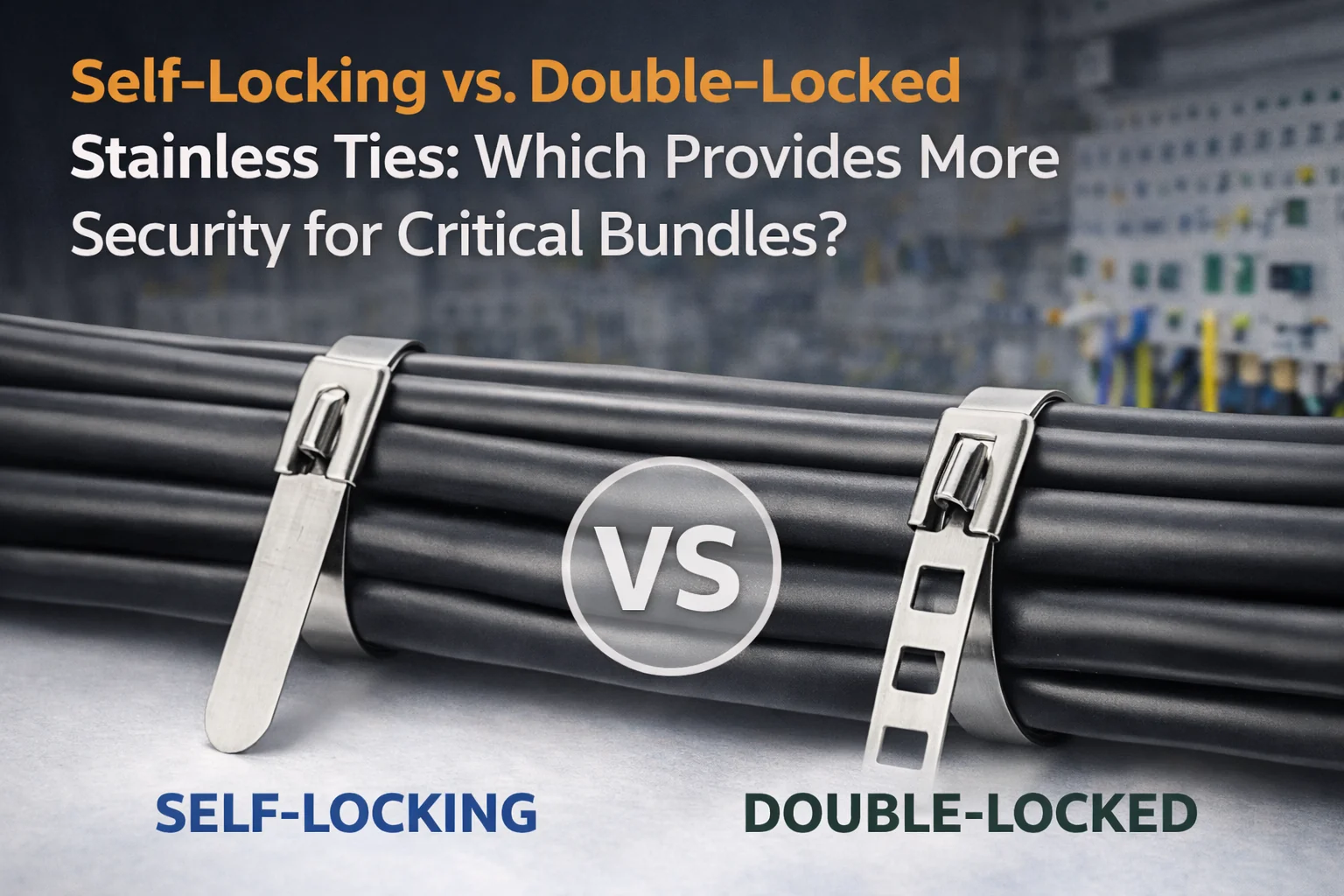

Self-Locking vs. Double-Locked Stainless Ties: Which Provides More Security for Critical Bundles?

In demanding industrial, marine, and infrastructure applications, securing a bundle is not just about organization—it’s about safety, reliability, and preventing catastrophic failure. When a cable tie loosens due to vibration, thermal cycling, or accidental impact, the consequences can be severe.

Read More →Admin

The Guide to Stainless Steel Cable Tie Mounts and Bases for Secure Anchoring

A stainless steel cable tie is only as strong and reliable as its anchor point. In demanding industrial, marine, and outdoor applications, securing a bundle directly to a structure isn’t always possible or safe. This is where stainless steel cable

Read More →Admin

What are Releasable Stainless Steel Cable Ties and When Should You Use Them?

In the world of industrial fastening and organization, stainless steel cable ties have long been the go-to solution for demanding environments. But what happens when you need a secure bundle today that might need to be reconfigured tomorrow? Enter the

Read More →Admin

What Makes Stainless Steel Cable Ties Stronger Than Nylon Ties?

Introduction When it comes to securing cables and bundles, Stainless Steel Cable Ties often outperform their nylon counterparts in strength, durability, and resistance to harsh environments. For procurement professionals, understanding why stainless steel ties are stronger and when to choose them can

Read More →Admin

Why Material and Strength Matter When Selecting Stainless Steel Tie Wraps

Introduction Selecting the right stainless steel cable ties directly impacts installation safety, long-term durability, and overall project reliability. Material grade, tensile strength, tie length, and environmental resistance all determine whether your system performs flawlessly—or fails early. This guide helps procurement

Read More →Admin

7 Key Factors to Consider Before Buying Stainless Steel Cable Ties

Introduction When it comes to securing cables, pipes, or heavy-duty industrial components, stainless steel cable ties are the most reliable solution. Not all ties are the same—choosing the wrong one can lead to frequent replacements, safety risks, and unnecessary costs.

Read More →Admin

Top 5 Industries That Rely on Stainless Steel Tie Wraps

Introduction For industrial professionals, securing cables, pipes, or components in harsh environments is a critical challenge. While plastic zip ties may work for simple tasks, they often fail under heat, corrosion, or mechanical stress. Stainless steel tie wraps provide superior

Read More →Admin

What Makes Stainless Steel Cable Ties Better Than Nylon Ties?

Introduction When it comes to securing cables, pipes, or even heavy-duty industrial components, the choice of tie matters more than you might think. Stainless steel cable ties stand out as the go-to solution for durability, reliability, and safety — far

Read More →Admin

What Are the Different Types of Stainless Steel Cable Ties?

Introduction If you’re in industrial or construction procurement, you know stainless steel cable ties are non-negotiable for securing cables, pipes, and components in harsh environments. But with diverse options tailored to specific scenarios, choosing the right one can be tricky.

Read More →Admin

Understanding Grades: 304 vs 316 Stainless Steel Cable Ties Explained

Choosing between 304 and 316 stainless steel cable ties is one of the most important decisions for anyone needing durable, corrosion-resistant fastening. Pick the wrong grade, and you risk premature rust, breakage, or costly replacements—especially in marine or chemical environments. Every

Read More →Admin

The Difference Between Coated and Uncoated Stainless Steel Cable Ties

Introduction Stainless steel cable ties are a go-to for heavy-duty fastening—but choosing between coated and uncoated variants can make or break your project. Both use durable stainless steel (usually 304 or 316 grade) for strength and corrosion resistance, but the added coating in one changes

Read More →