What Makes Stainless Steel Cable Ties Better Than Nylon Ties?

Introduction

When it comes to securing cables, pipes, or even heavy-duty industrial components, the choice of tie matters more than you might think. Stainless steel cable ties stand out as the go-to solution for durability, reliability, and safety — far beyond what nylon ties can offer.

Whether you’re managing installations in marine, chemical, or industrial environments, understanding why stainless steel ties outperform nylon can help you make smarter, long-term procurement decisions.

XIXI is an ISO 9001–certified supplier specializing in stainless steel fastening solutions for the marine, oil & gas, and industrial sectors. Our products are field-tested for corrosion resistance and tensile strength under extreme conditions.

What Makes Stainless Steel Cable Ties More Durable Than Nylon?

Why Stainless Steel Wins on Strength and Longevity

Durability is where stainless steel ties truly shine. Unlike nylon, which can weaken and crack under extreme temperatures or UV exposure, stainless steel ties are built to last.

-

Exceptional tensile strength — handles loads 2–10× heavier than nylon ties.

-

UV and temperature resistant from -80°C to 538°C without loss of performance.

-

Non-brittle design that prevents cracking over time.

-

Perfect for heavy-duty use in oil & gas, shipbuilding, and power distribution.

-

Reduces maintenance, replacement frequency, and safety risks.

TL;DR: Stainless steel ties stay strong and stable long after nylon has degraded, saving you downtime and cost in demanding environments.

Why Are Stainless Steel Cable Ties More Corrosion-Resistant?

The Stainless Advantage in Harsh Conditions

Corrosion resistance is critical in environments exposed to salt, moisture, and chemicals. 316-grade stainless steel cable ties outperform nylon ties in every category.

-

Made from 304 or 316 stainless steel for superior corrosion resistance.

-

Withstand acidic, alkaline, and saline environments without rust.

-

Ideal for outdoor, offshore, and chemical plant installations.

-

Prevent rust stains, contamination, or equipment damage.

-

Maintain mechanical integrity for years under exposure.

How Do Stainless Steel Cable Ties Improve Safety and Security?

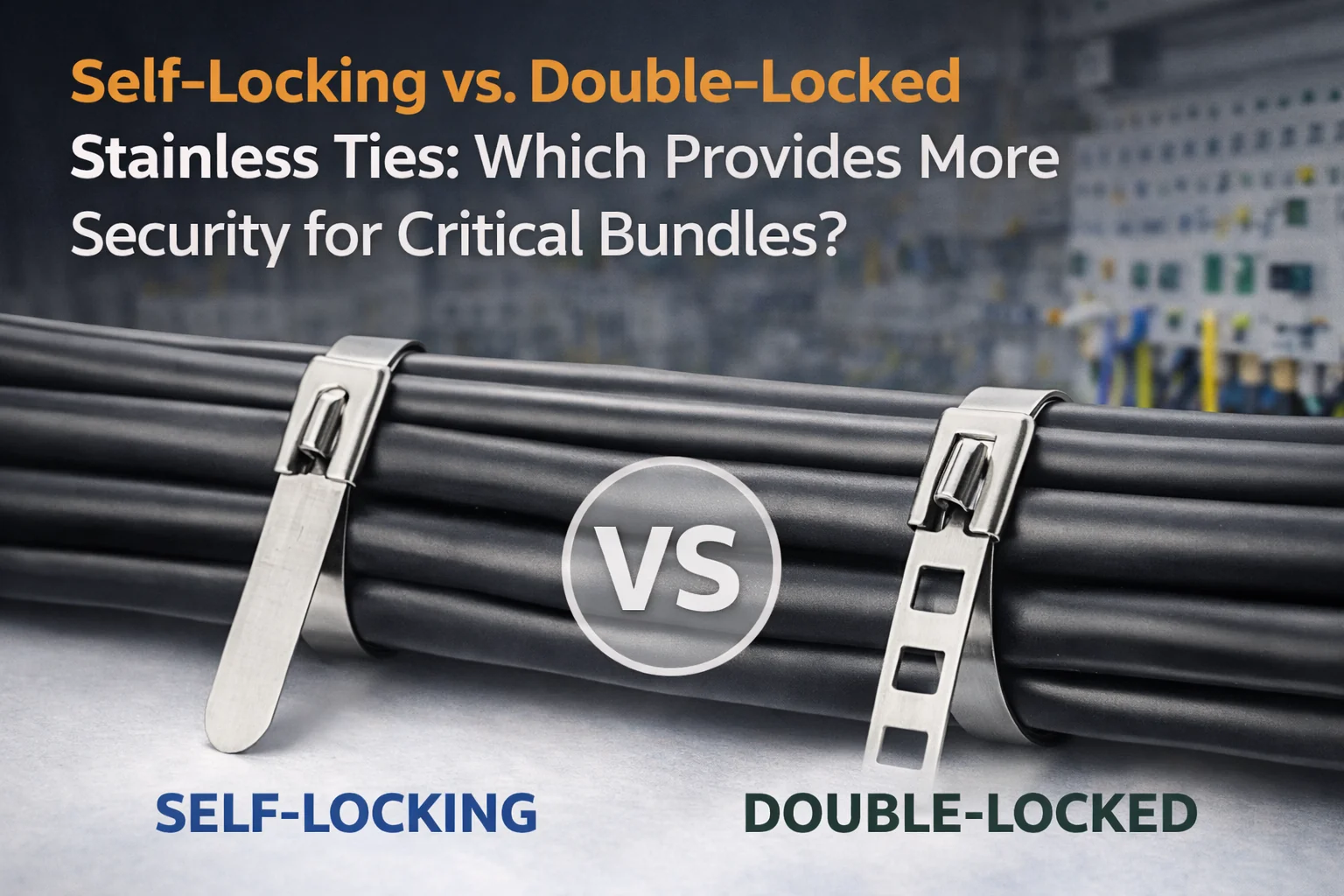

Advanced Locking and Tamper-Proof Design

Safety is more than just strength — it’s about control. Stainless steel cable ties use secure locking mechanisms that provide superior protection.

-

Ball-lock or self-locking designs resist loosening under vibration.

-

Tamper-proof seals prevent unauthorized removal.

-

High temperature safety — maintain clamping force under heat.

-

Comply with industrial standards like UL and ASTM.

-

Perfect for transportation, energy, and defense applications.

In environments where equipment integrity and safety are critical, stainless steel ties ensure a locked, secure, and compliant installation.

How Versatile Are Stainless Steel Cable Ties?

Suitable for Almost Any Application

From simple electrical wiring to complex industrial bundling, stainless steel cable ties offer exceptional versatility.

-

Available in multiple widths, lengths, and strengths (50–500+ lbs).

-

Can be coated with nylon or PVC for abrasion resistance and color coding.

-

Work seamlessly with steel bands and clamps for large bundles.

-

Ideal for permanent or temporary use in construction, marine, and manufacturing.

-

Compatible with manual or pneumatic installation tools.

Their adaptability means one product line can serve multiple departments — from maintenance to field installation.

How Do Stainless Steel Cable Ties Save Costs Long-Term?

Investing in Quality That Pays for Itself

While stainless steel ties have a higher initial cost than nylon, their total lifecycle cost is much lower.

-

Fewer replacements mean lower maintenance expenses.

-

Reduced downtime from tie failure or breakage.

-

Less equipment damage due to tie degradation.

-

Bulk and wholesale options lower procurement cost per unit.

-

Proven return on investment through extended service life.

Bottom line: Paying slightly more upfront saves exponentially over time — especially in industrial or outdoor applications.

Stainless Steel Cable Ties vs Nylon: Quick Comparison Table

| Feature | Stainless Steel Cable Ties | Nylon Cable Ties | Material Grade | Typical Applications | Corrosion Resistance |

|---|---|---|---|---|---|

| Tensile Strength | 50 – 500+ lbs | 18 – 50 lbs | 304, 316 Stainless Steel | Industrial, Marine, Security | Excellent |

| Temperature Range | -80°C to 538°C | -40°C to 85°C | Various | Outdoor, Chemical Plants | Superior to Nylon |

| UV Resistance | Excellent | Poor | Stainless Steel | Outdoor Installations | Long-term durability |

| Locking Mechanism | Steel Buckle, Ball Lock | Plastic Teeth | Stainless Steel | Security, Heavy Duty | Tamper-proof |

| Chemical Resistance | High (Acids, Alkalis) | Moderate | 316 Stainless Steel | Chemical, Marine | Outstanding |

| Reusability | Limited (some releasable) | Usually single-use | Stainless Steel | Maintenance, Temporary Use | Long-lasting |

Case Study: Real Results from an Industrial Application

A marine engineering client replaced nylon ties with 316 stainless steel cable ties across a seawater pumping station. After 18 months of operation:

-

0 failures due to corrosion or stress.

-

Maintenance costs reduced by 42%.

-

Downtime decreased by 30%.

-

Improved safety compliance with ISO and NACE standards.

Result: A single upgrade improved operational reliability and delivered measurable ROI within one year.

Conclusion

When comparing stainless steel cable ties to nylon, the difference is clear — superior strength, corrosion resistance, safety, and cost efficiency make them the professional’s choice.

For engineers and procurement specialists, investing in high-grade stainless steel zip ties ensures long-term reliability, especially in demanding industrial and marine environments.

Ready to upgrade your cable management solutions? Contact XIXI today to request a datasheet or sample — and experience true durability in every installation.

Frequently Asked Questions

Q: Are stainless steel cable ties reusable?

A: Most are single-use, but some releasable designs exist for temporary installations or maintenance applications.

Q: What environments are stainless steel cable ties best suited for?

A: Harsh environments such as marine, chemical plants, outdoor sites, and high-temperature zones.

Q: Can stainless steel cable ties be coated?

A: Yes, coatings like PVC or nylon prevent abrasion and offer color identification.

Q: How do stainless steel cable ties compare in cost to nylon?

A: They cost more initially but last longer, reducing total ownership and maintenance costs.

Q: What sizes are available?

A: Sizes range from miniature 100mm ties for electrical use to heavy-duty 1000mm straps for industrial bundling.