7 Key Factors to Consider Before Buying Stainless Steel Cable Ties

Introduction

When it comes to securing cables, pipes, or heavy-duty industrial components, stainless steel cable ties are the most reliable solution. Not all ties are the same—choosing the wrong one can lead to frequent replacements, safety risks, and unnecessary costs. In this guide, XIXI shares 7 key factors procurement professionals should consider to select the right stainless steel cable ties for industrial, marine, electrical, or chemical applications.

Understanding Stainless Steel Cable Ties

What Are Stainless Steel Cable Ties?

Also known as stainless steel zip ties or tie wraps, these heavy-duty fasteners are designed to withstand harsh environments. Unlike plastic ties, stainless steel options provide superior strength, chemical resistance, and long-term durability, making them ideal for outdoor, marine, and industrial applications.

Why Choose Stainless Steel?

Stainless steel resists rust, UV, chemicals, and extreme temperatures. Grades like 316 stainless steel offer even higher corrosion resistance, especially in saltwater or chemical-heavy environments. XIXI recommends considering the environment carefully to select the most suitable grade.

1. Material Grade and Corrosion Resistance

Choosing the right grade is critical:

-

304 Stainless Steel: Good corrosion resistance, suitable for general industrial environments.

-

316 Stainless Steel: Superior resistance to saltwater and chemicals, ideal for marine and chemical plants.

-

Comparison Table:

| Feature | 304 Stainless Steel | 316 Stainless Steel | Best Use Case |

|---|---|---|---|

| Corrosion Resistance | Good | Excellent | Marine, chemical plants |

| Cost | Moderate | Higher | High-demand environments |

| Temperature Tolerance | -80°C to 538°C | -80°C to 538°C | Extreme conditions |

2. Tensile Strength and Load Capacity

Ensure the tie can handle the expected load:

-

Check the tensile strength rating—higher strength is necessary for heavy or vibrating components.

-

Avoid overestimating strength to prevent unnecessary costs.

-

XIXI suggests choosing ties slightly above your maximum load requirement for safety.

3. Tie Length and Width Options

Size matters depending on your bundles:

-

Longer ties handle larger bundles or thicker objects.

-

Wider ties offer more strength but less flexibility.

-

Typical sizes: 4 inches to 48 inches in length, 0.10 to 0.50 inches in width.

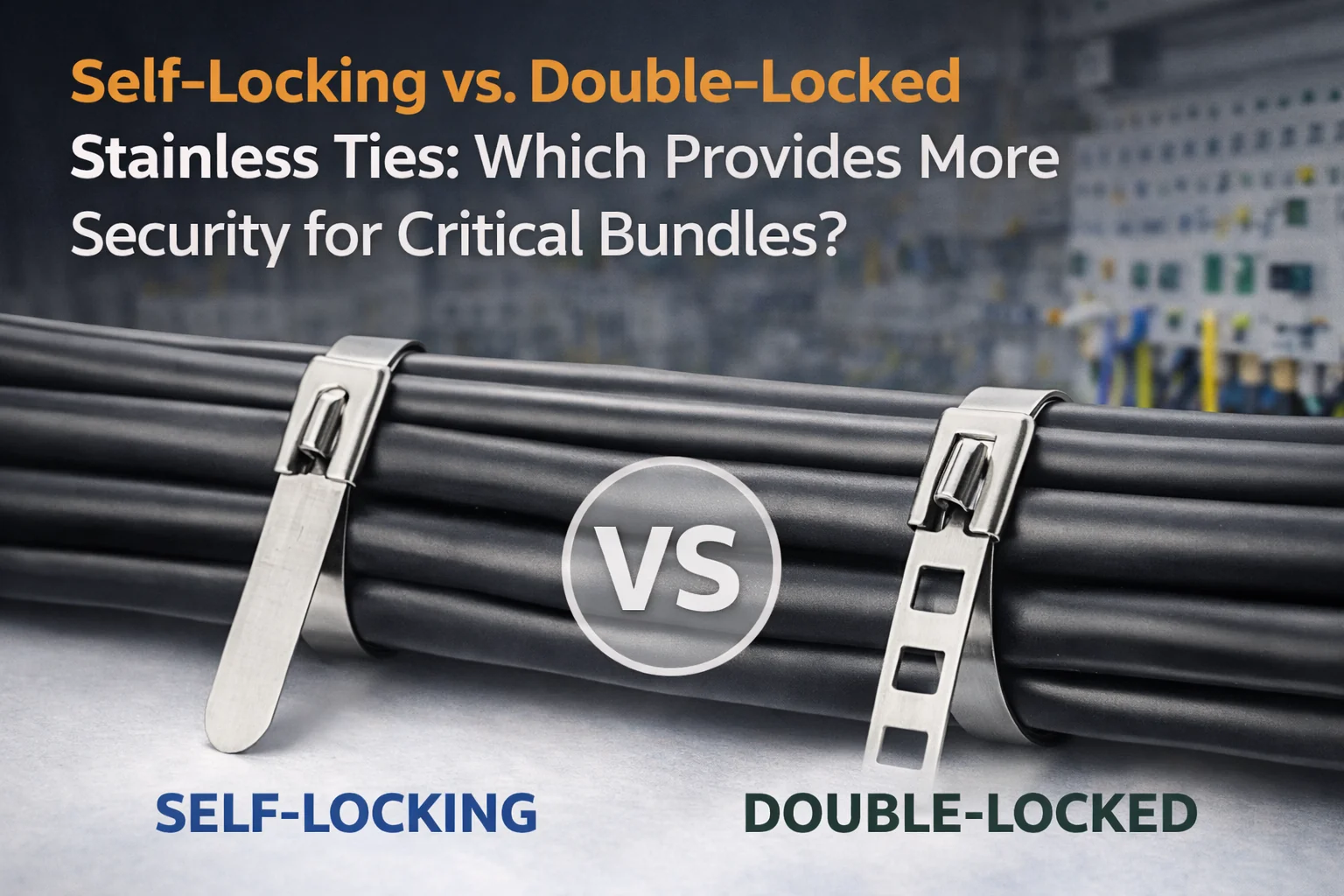

4. Locking Mechanism and Ease of Installation

The locking system affects security and installation speed:

-

Self-locking ties: Quick installation, suitable for tight spaces.

-

Tool-assisted ties: Required for heavy-duty applications.

-

Consider high-volume jobs—quicker systems reduce labor costs.

5. Environmental and Chemical Resistance

Think beyond corrosion:

-

Exposure to UV, chemicals, and extreme temperatures may degrade materials.

-

316 stainless steel performs best in marine, chemical, and industrial environments.

-

Always check compatibility with specific chemicals.

6. Compliance and Standards

Ensure your ties meet industry requirements:

-

Certifications like RoHS, REACH, UL demonstrate safety, quality, and environmental responsibility.

-

Critical for aerospace, food, and pharmaceutical industries.

7. Supplier Reliability and Cost Efficiency

Your supplier matters:

-

XIXI emphasizes choosing suppliers with proven quality control and consistent delivery.

-

Bulk purchasing reduces costs but confirm minimum order quantities.

-

Lead times and after-sales support are critical for project planning.

Real-World Applications

Industrial Plant Upgrade

A manufacturing plant replaced plastic ties with stainless steel ties to prevent corrosion in a humid environment. Maintenance downtime decreased, and safety improved.

Marine Facility

316 stainless steel ties prevented frequent replacements in a coastal facility, saving costs over time.

Electrical Installation

High-tensile ties with reliable locking mechanisms ensured secure and long-lasting cable bundling.

Maintenance and Handling Tips

-

Store ties in dry, clean environments.

-

Use proper installation tools to prevent damage.

-

Regularly inspect critical ties for wear or loosening.

Stainless Steel Cable Tie Specifications

| Feature | Typical Range | Notes |

|---|---|---|

| Material Grade | 304, 316 | 316 for harsher environments |

| Tensile Strength | 50 – 250 lbs | Depends on width and thickness |

| Length | 4–48 inches | Choose based on bundle size |

| Width | 0.10–0.50 inches | Wider = stronger but less flexible |

| Locking Type | Self-locking, Tool-assisted | Tool-assisted for heavy-duty use |

| Temperature Range | -80°C to 538°C | Suitable for extreme conditions |

FAQs

Q1: What is the difference between 304 and 316 stainless steel cable ties?

A: 316 offers higher corrosion resistance, especially for marine and chemical environments. 304 is suitable for general industrial applications.

Q2: Can stainless steel cable ties be reused?

A: Generally, no—self-locking ties are designed for one-time use.

Q3: How do I choose the right length and width?

A: Base it on bundle size and tensile requirements. Longer/wider ties handle bigger loads.

Q4: Are special tools needed for installation?

A: Some heavy-duty ties require tool-assisted tightening and cutting.

Q5: Where can I buy stainless steel cable ties wholesale?

A: XIXI and other trusted industrial suppliers provide bulk options for various applications.

Conclusion

Choosing the right stainless steel cable ties requires considering material grade, tensile strength, size, locking mechanism, environmental resistance, compliance, and supplier reliability to ensure secure, durable, and cost-effective solutions for industrial, marine, electrical, or chemical applications. XIXI is committed to helping procurement professionals make informed choices—explore our full range of stainless steel cable ties, request a free consultation, or contact our sales team today to find the perfect solution for your application.