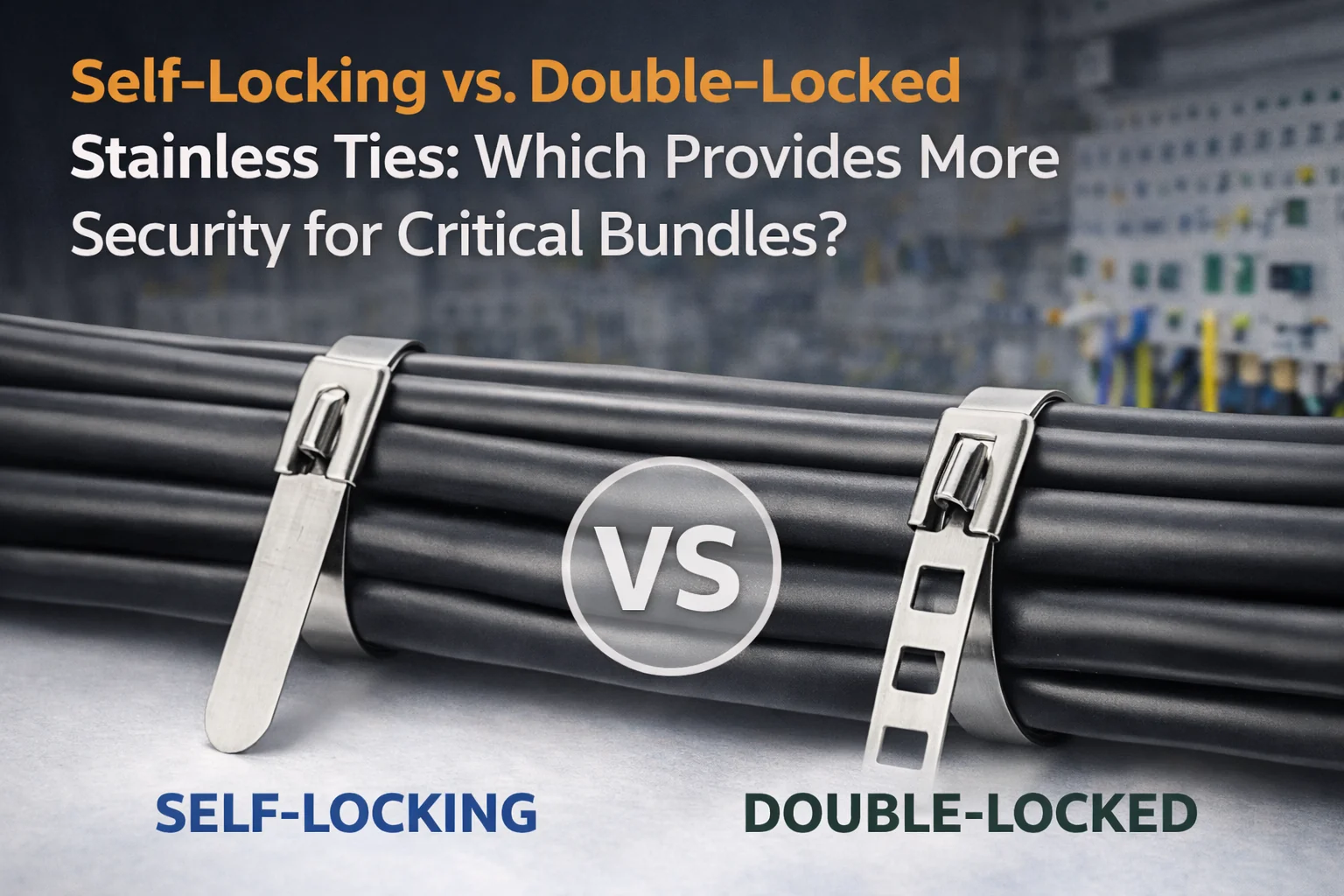

Self-Locking vs. Double-Locked Stainless Ties: Which Provides More Security for Critical Bundles?

In demanding industrial, marine, and infrastructure applications, securing a bundle is not just about organization—it’s about safety, reliability, and preventing catastrophic failure. When a cable tie loosens due to vibration, thermal cycling, or accidental impact, the consequences can be severe. This brings us to a critical choice: the standard self-locking stainless steel tie or the more robust double-locked variant. Understanding the fundamental difference in their locking mechanisms is key to selecting the right fastener for applications where failure is not an option. This guide will clearly explain how each type works and provide a definitive comparison to help you ensure maximum security for your most critical installations. At Xinxing, we engineer both solutions to meet the highest standards of performance and durability.

Defining “Critical Bundles” and the Need for Superior Security

What constitutes a “critical bundle”? These are cable and hose assemblies where a securing failure would lead to significant risk or cost. This includes: Safety-Critical Systems (fire detection wiring, emergency shutdown controls), High-Vibration Environments (engines, motors, heavy machinery, vehicles), Essential Infrastructure (bridge sensors, telecommunications, power distribution), and Hard-to-Access Locations (underground conduits, offshore platforms, cleanrooms). In these scenarios, a standard tie that might slowly loosen over time is insufficient. The requirement is for a locking mechanism that actively resists back-out, maintains constant tension, and provides verifiable security, justifying the need to compare the inherent designs of self-locking and double-locked ties.

How Self-Locking Stainless Steel Ties Work

The self-locking (or standard pawl-and-ratchet) tie is the most common design. It features a flexible stainless steel band with angled teeth and a locking head containing a flexible pawl. When the tail is inserted and pulled tight, the pawl engages the teeth, preventing it from being pulled back out. The security relies on the spring tension of the pawl pressing against the teeth. While effective for general use, this design has a potential point of failure: under persistent vibration or lateral force, the pawl can theoretically “ride” or “chatter” against the teeth, potentially allowing minimal, incremental loosening over an extended period. For many applications, this is acceptable, but for critical bundles, this single point of engagement is the vulnerability that double-locked designs address.

The Enhanced Security of Double-Locked Stainless Ties

Double-locked stainless steel ties incorporate a secondary locking feature that physically blocks the pawl from disengaging. The most common design adds a secondary tab, gate, or locking barbinside the head. Once the primary pawl engages the ratchet teeth, this secondary feature snaps into place behind the pawl or over the tail. This creates a positive mechanical block. Even if extreme vibration were to overcome the spring force of the primary pawl, the secondary lock prevents it from lifting enough to release the teeth. This dual-assurance mechanism provides a much higher degree of confidence against unintentional release, making it the preferred choice for applications subject to extreme dynamic forces or where long-term, maintenance-free reliability is paramount.

Head-to-Head Comparison: Security, Application, and Cost

The table below provides a direct, actionable comparison to guide your specification process.

| Feature | Self-Locking Stainless Tie | Double-Locked Stainless Tie |

|---|---|---|

| Locking Mechanism | Single, spring-loaded pawl engages ratchet teeth. | Primary pawl plus a secondary physical lock (tab/gate) that blocks pawl retreat. |

| Vibration & Shock Resistance | Good for moderate environments. | Excellent. Specifically engineered to resist loosening from high-frequency vibration and impact. |

| Tamper Resistance | Moderate. Can be cut or potentially pried open with tools. | High. The secondary lock often makes it more difficult to release intentionally without cutting. |

| Installation Effort | Standard. Requires standard tensioning and pulling. | Slightly higher. May require a firmer pull to fully engage both locks; a distinct “click” may be felt. |

| Visual Verification | Difficult to verify full engagement beyond a tight fit. | Often provides a visual or tactile confirmation (click, colored indicator) that the secondary lock is engaged. |

| Best For | General bundling, static installations, low-vibration panels, non-critical supports. | Critical Bundles: Engine compartments, rail/aviation systems, seismic zones, safety wire, permanent infrastructure. |

| Cost Consideration | Lower cost per unit. Economical for high-volume, non-critical use. | Higher initial cost, but provides insurance against failure, reducing long-term risk and maintenance cost. |

How to Choose: Selecting the Right Tie for Your Security Level

Making the correct choice is a straightforward risk assessment. Follow this decision pathway:

-

Assess the Environment: Is the application subject to constant vibration, thermal cycling, or mechanical shock? If yes, the double-locked tie is strongly recommended.

-

Evaluate the Consequence of Failure: What happens if the bundle comes loose? If the answer involves safety hazards, operational downtime, environmental damage, or high repair costs, the investment in double-locked security is justified.

-

Consider Inspection and Maintenance: For hard-to-access or permanent installations where inspection is infrequent or impossible, the added assurance of a double-lock provides long-term peace of mind.

-

Match to Industry Standards: Many industries (e.g., aerospace, mass transit, nuclear) have explicit specifications for high-vibration zones that effectively mandate a double-locking or similarly failsafe mechanism.

For general panel organization, securing a static ground wire, or bundling low-risk cables in a controlled environment, a high-quality self-locking tie from Xinxing is perfectly capable and cost-effective.

Installation Best Practices for Maximum Security

Regardless of type, proper installation is key. Use the correct tool for consistent tension; hand-tightening is unreliable for critical applications. Never overtighten—this can damage cables or deform the tie head, compromising the lock. For double-locked ties, ensure you hear/feel the positive engagement of the secondary mechanism. Always trim tails cleanly to avoid sharp edges. For the highest-security applications, consider Xinxing’s proprietary locking designs that may include sealable or tamper-evident features for verification.

Conclusion

For general-purpose bundling, a standard self-locking tie offers a reliable, economical solution. However, for bundles where failure poses a significant risk—especially in high-vibration or inaccessible locations—the double-locked stainless steel tie provides demonstrably superior, failsafe security. It is the definitive choice for critical applications. When your project’s integrity depends on it, specify the enhanced protection of double-locked ties. For unmatched security and reliability, explore Xinxing’s range of high-performance double-locked stainless steel cable ties. Contact our engineering support team today to secure your most critical applications.

FAQ

Q: Can a double-locked tie be removed without cutting?

A: Typically, no. Most double-locked designs are intended to be permanent. Removal usually requires cutting the tie, as the secondary lock is not designed to be easily released.

Q: Are double-locked ties reusable?

A: Almost universally, no. Their permanent, high-security design makes them single-use. For reusable needs in critical applications, consider a specialty releasable clamp.

Q: Do double-locked ties have a higher tensile strength?

A: Not necessarily. The locking mechanism affects security against loosening, not necessarily the material’s tensile strength. Both types from the same series (e.g., Xinxing 316 stainless) will have similar tensile ratings.

Q: Is the installation tool different for double-locked ties?

A: Often, standard tensioning tools can be used. However, some advanced double-lock designs may benefit from a tool that ensures full seating of both locks. Always check the manufacturer’s recommendation.

Q: Why choose Xinxing for critical bundle security?

A: Xinxing designs and manufactures both standard and double-locked ties with rigorous quality control. Our expertise ensures you get a product with proven reliability, material integrity, and the precise security level your application demands.