The Complete Guide to Stainless Cable Ties: Types, Uses, and Benefits

Introduction

When you need to secure cables, pipes, or equipment—especially in harsh conditions—plastic cable ties often fall short. They crack in cold, melt in heat, and corrode in moisture, leaving your installations at risk. But stainless cable ties (also called stainless steel zip ties) solve these problems. Built for strength, durability, and resistance to the elements, they’re the go-to choice for heavy-duty and long-term fastening. This guide breaks down everything you need to know: their types, top uses, key benefits, and how to choose the right one for your project.

What Are Stainless Cable Ties?

Stainless cable ties are heavy-duty fastening devices made from high-grade stainless steel. Unlike plastic ties, they’re engineered to withstand extreme temperatures, corrosion, and high tensile loads—making them ideal for industrial, outdoor, and high-stress applications.

At their core, most stainless cable ties have two main parts:

Tie Body: A flexible stainless steel strip with evenly spaced teeth (for locking).

Locking Mechanism: A small clasp (usually stainless steel) with a pawl or ball bearing that grips the teeth, creating a tight, non-slip hold.

Types of Stainless Cable Ties: Choose the Right Fit

Not all stainless cable ties are the same. They’re categorized by material, lock type, coating, and strength—each designed for specific needs.

By Material Grade

The stainless steel grade determines corrosion resistance and durability. These are the two most common:

304 Stainless Steel Cable Ties: The “general-purpose” option. Resists rust, moisture, and mild chemicals. Perfect for indoor industrial settings, construction, and outdoor projects not exposed to saltwater.

316 Stainless Steel Cable Ties: The “marine-grade” choice. Adds molybdenum for extra resistance to saltwater, harsh chemicals, and extreme humidity. Ideal for boats, offshore platforms, coastal infrastructure, and chemical plants.

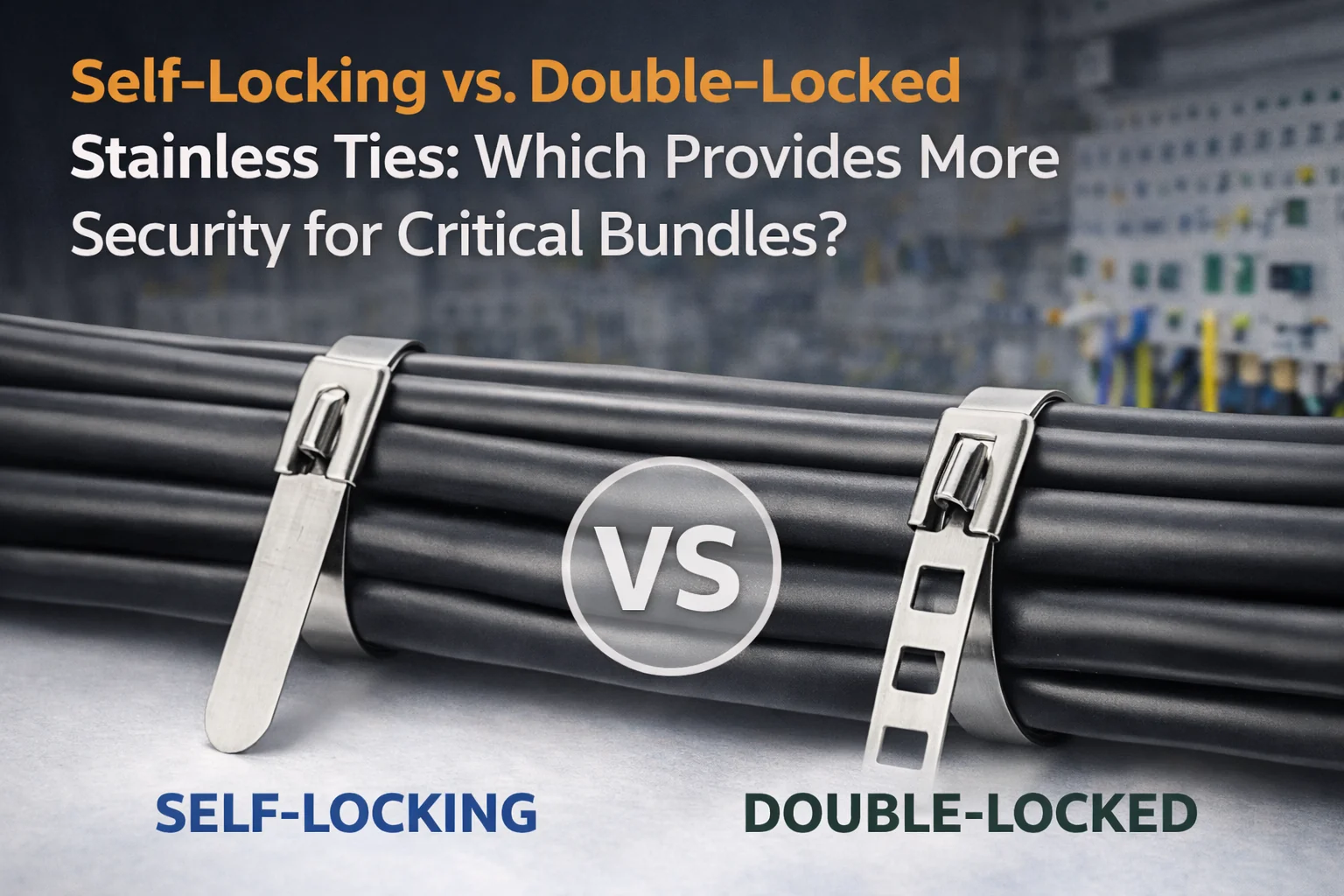

By Lock Type

Lock design dictates whether the tie is reusable or permanent:

Non-Releasable (One-Time Use): The most common type. Once tightened, the pawl locks the teeth—you can only remove it by cutting. Great for permanent installations (e.g., electrical wiring in buildings).

Releasable (Reusable): Features a manually adjustable pawl. Press the pawl to disengage the teeth, allowing you to loosen or reposition the tie. Perfect for temporary projects (e.g., equipment testing) or installations that need adjustments.

By Coating

Coatings protect delicate surfaces from scratches or add extra insulation:

PVC-Coated Stainless Cable Ties: Soft PVC layer prevents scratching on polished pipes, electrical cables, or painted surfaces. Also adds a small amount of insulation for electrical applications.

Nylon-Coated Stainless Cable Ties: More durable than PVC. Offers better resistance to abrasion and high temperatures. Used for heavy machinery or sharp-edged bundles.

By Strength (Tensile Load)

Tensile strength (measured in pounds) tells you how much weight the tie can hold before breaking:

Standard Strength: 50–100 lbs. For light-to-medium bundles (e.g., small cable groups, HVAC ducts).

Heavy-Duty: 100–250 lbs. For large bundles, heavy pipes, or industrial equipment.

Extra-Heavy-Duty: 250+ lbs. Used for heavy machinery, aerospace components, or large structural bundles.

Key Uses of Stainless Cable Ties

Stainless cable ties shine in environments where plastic ties fail. Here are their most common applications across industries:

- Construction & Building

Secure electrical cables, plumbing pipes, and HVAC ducts in commercial or residential buildings.

Bundle rebar or structural wires in concrete projects (resists rust during construction and long-term use).

- Marine & Coastal Applications

Fasten wires, hoses, and navigation equipment on boats, yachts, or offshore oil rigs (316 stainless steel is mandatory here for saltwater resistance).

Secure dock hardware or coastal lighting wiring (withstands constant moisture and salt spray).

- Automotive & Aerospace

Organize wiring harnesses under car hoods (tolerates high temperatures from engines).

Secure lightweight components in aircraft (meets strict durability and weight standards).

- Industrial Manufacturing

Bundle production line cables, heavy machinery parts, or chemical plant pipes (resists oils, solvents, and high-pressure washing).

Secure conveyor belt components or assembly line tools (handles vibration and frequent use).

- Outdoor Infrastructure

Fasten streetlight wiring, telecommunications cables, or solar panel mounts (withstands rain, UV radiation, and extreme temperatures).

Secure traffic signal cables or highway guardrail hardware (resists wind, debris, and corrosion).

- DIY & Home Projects

Secure outdoor lighting cables, garden hoses, or patio furniture (no need to replace yearly like plastic ties).

Bundle garage storage items (e.g., power tool cords) that are exposed to grease or moisture.

Benefits of Stainless Cable Ties (vs. Plastic Ties)

Stainless cable ties offer clear advantages over plastic—especially for demanding projects. Here’s why they’re worth the investment:

- Unmatched Durability

Lasts 10–20 years (vs. 1–3 years for plastic ties). Reduces maintenance costs and the need for frequent replacements.

Resists wear, tear, and impact—even in high-vibration environments (e.g., factories, cars).

- Extreme Temperature Tolerance

Works from -40°F (-40°C) (cold winters, freezers) to 1,000°F (538°C) (engine bays, industrial ovens). Plastic ties become brittle below 32°F (0°C) and melt above 180°F (82°C).

- Superior Corrosion Resistance

304 and 316 stainless steel resist rust, moisture, and chemicals. Plastic ties degrade in UV light, saltwater, or harsh cleaners.

- Higher Tensile Strength

Can hold 50–500 lbs (depending on type). Plastic ties typically max out at 20–50 lbs—making them useless for heavy bundles.

- Tamper Resistance

Non-releasable locks are hard to break or manipulate. Critical for sensitive applications (e.g., security systems, electrical grids).

- Versatility

Available in lengths (4–48 inches) and widths (0.12–0.5 inches) to fit any bundle. Plastic ties have limited size options for heavy-duty use.

How to Choose the Right Stainless Cable Tie

Follow these 5 steps to pick a tie that matches your project:

Start with the Environment:

Indoor/general use: 304 stainless steel.

Marine/coastal/chemical settings: 316 stainless steel.

Check Tensile Strength:

Calculate the weight of your bundle (e.g., 50 lbs for a small cable group, 200 lbs for heavy pipes). Choose a tie with a strength rating 10–20% higher than the bundle weight (for safety).

Pick the Right Length:

Measure the circumference of your bundle, then add 2–3 inches (for a snug fit and trimming excess). For example, a 10-inch circumference bundle needs a 12–13 inch tie.

Choose Lock Type:

Permanent installation: Non-releasable.

Temporary/adjustable: Releasable.

Add Coating (If Needed):

Delicate surfaces (polished metal, painted pipes): PVC or nylon coating.

Rough/abrasive bundles: Uncoated (more grip).

FAQ

Q: Can I reuse stainless cable ties?

A: Only releasable models are reusable. Non-releasable ties must be cut to remove, so they’re one-time use.

Q: How do I cut stainless cable ties safely?

A: Use heavy-duty wire cutters, bolt cutters, or specialized cable tie cutters. Avoid regular scissors—they’ll bend the steel and leave sharp edges. Wear gloves to protect your hands.

Q: Are stainless cable ties expensive?

A: They cost more upfront (usually $0.50–$5 per tie) than plastic ties ($0.05–$0.20). But their long lifespan (10+ years) means lower long-term costs than replacing plastic ties yearly.

Q: Can stainless cable ties be used with electrical cables?

A: Yes—especially PVC-coated models (they add mild insulation). Just ensure the tie isn’t over-tightened (to avoid damaging cables).

Q: Do stainless cable ties rust?

A: No—304 and 316 stainless steel form a protective oxide layer that stops rust. Only low-grade stainless steel (not used for cable ties) will rust.

Final Thoughts

Stainless cable ties aren’t just “better plastic ties”—they’re a long-term solution for fastening needs that demand strength, durability, and reliability. Whether you’re working on a marine project, industrial installation, or outdoor DIY task, choosing the right type (304 vs. 316, releasable vs. non-releasable) will ensure your bundles stay secure for years.

If you’re still unsure which stainless cable tie fits your project, contact us! —we’ll help you pick the perfect one!